Introduction

In the increasingly competitive global aluminum door and window industry, reducing production costs is crucial for companies to remain competitive. For Saudi aluminum door and window manufacturers, the Chinese supply chain offers significant cost optimization opportunities.

Through effective procurement strategies, optimized logistics, and supplier management, Saudi companies can significantly reduce raw material, production, and transportation costs, ultimately achieving overall cost reductions of 30% or more.

This article will delve into how Saudi aluminum door and window manufacturers can leverage the Chinese supply chain to achieve cost optimization, covering key factors such as procurement strategies, supplier selection, logistics optimization, and quality control, and provide practical implementation recommendations.

- Why choose the China supply chain?

- 1.1 Cost advantage of China’s aluminum profiles and hardware accessories

- China is the world’s largest producer of aluminum profiles, with a complete industrial chain and economies of scale, making the cost of raw materials much lower than the international market. For example:

- The price of aluminum profiles is 20%-30% lower than that in the European market.

- The prices of hardware accessories (such as locks, pulleys, and hinges) are 40%-50% lower than those of European and American brands.

- China is the world’s largest producer of aluminum profiles, with a complete industrial chain and economies of scale, making the cost of raw materials much lower than the international market. For example:

- 1.2 Mature manufacturing technology and production capacity guarantee

- China has the world’s leading aluminum door and window processing technology, with a high degree of automation and high production efficiency, which can meet the needs of large-volume orders.

- 1.3 Complete export supporting services

- Chinese suppliers are familiar with international trade rules and can provide a variety of trade methods, such as EXW, FOB, CIF, and assist in handling customs clearance, logistics, and other issues.

- 1.1 Cost advantage of China’s aluminum profiles and hardware accessories

- Key Strategy: How to reduce costs through the Chinese supply chain?

- 2.1 Optimize Procurement Strategy

- Centralize procurement to improve bargaining power

- Establish long-term partnerships with several core suppliers to secure volume discounts.

- Use annual framework agreements to lock in preferential prices.

- Use B2B platforms to find high-quality suppliers

- Screen suppliers through platforms such as Alibaba, Made-in-China, and Global Sources.

- Compare multiple quotations and select the partner with the best value for money.

- Centralize procurement to improve bargaining power

- 2.2 Selecting the right supplier

- Examining supplier qualifications

- Check the factory size, production equipment, and quality management system (such as ISO 9001 certification).

- Request samples and conduct rigorous testing.

- Evaluate the supplier’s export experience

- Prefer suppliers with Middle East export experience to ensure that their products meet Saudi standards (such as SASO certification).

- Examining supplier qualifications

- 2.3 Optimize logistics and transportation costs

- Ocean freight vs. air freight

- Aluminum profiles and door and window accessories are suitable for ocean freight, which is 60%-80% cheaper than air freight.

- Use LCL (less than container load) or FCL (full container load) for transportation, and choose the most economical option based on the

- order volume.

- Choose a reliable freight forwarder

- Work with a professional freight forwarder on Middle East routes to optimize transportation routes and reduce transit time.

- Use “door-to-door” (DDP) logistics services to reduce customs clearance risks.

- Ocean freight vs. air freight

- 2.4 Quality Control and Inspection

- Third-party inspection (e.g., SGS, BV)

- Inspect products before shipment to ensure they meet contract requirements.

- Avoid returns or additional costs due to quality issues.

- Establish a long-term quality monitoring mechanism

- Regularly audit suppliers to ensure production stability.

- Use a digital management system (e.g., ERP) to track order quality.

- Third-party inspection (e.g., SGS, BV)

- 2.1 Optimize Procurement Strategy

- Success Case Study: Saudi Aluminum Door and Window Factory Reduces Costs by 30%

- 3.1 Case Background

- A medium-sized Saudi aluminum door and window manufacturer (with an annual procurement volume of approximately US$5 million) faced rising raw material costs in Europe and decided to shift to a Chinese supply chain.

- 3.2 Implementation Steps

- Supplier Screening: Three SASO-compliant aluminum profile suppliers were identified through Alibaba.

- Price Negotiation: An annual procurement agreement was signed, resulting in a 15% price discount.

- Logistics Optimization: Sea freight was adopted, saving 70% compared to air freight.

- Quality Control: SGS was commissioned for pre-shipment inspection to reduce returns.

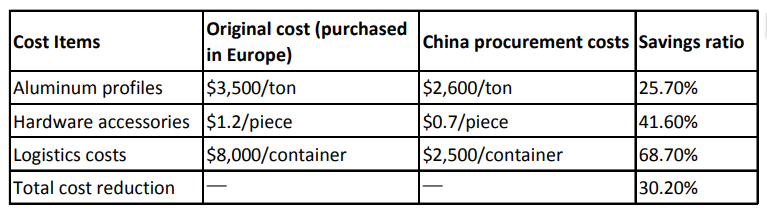

- Cost savings results

- 3.1 Case Background

- Potential Challenges and Countermeasures

- 4.1 Language and Cultural Differences

- Solution: Hire a Chinese-speaking purchasing agent or use professional translation services.

- 4.2 Delivery Delay Risk

- Solution: Clearly stipulate delivery timelines and include a penalty clause in the contract.

- 4.3 Impact of Exchange Rate Fluctuations

- Solution: Use RMB settlement or utilize foreign exchange hedging instruments (such as forward contracts).

- 4.1 Language and Cultural Differences

- Conclusion

- By optimizing its Chinese supply chain, Saudi Arabian aluminum door and window manufacturers can significantly reduce procurement, production, and logistics costs, achieving savings of over 30%. The key lies in:

- Selecting cost-effective suppliers

- Optimizing procurement and logistics strategies

- Strong quality control

- Establishing long-term partnerships

- As China-Saudi Arabia economic and trade cooperation deepens, the Chinese supply chain will become a crucial driver of cost reduction and efficiency improvement in Saudi Arabia’s manufacturing industry.

- By optimizing its Chinese supply chain, Saudi Arabian aluminum door and window manufacturers can significantly reduce procurement, production, and logistics costs, achieving savings of over 30%. The key lies in:

FAQ

Q1: Is the quality of Chinese aluminum profiles reliable?

A: China has many aluminum profile manufacturers with international certifications (such as ISO 9001 and SGS). As long as we rigorously screen suppliers and conduct product inspections, the quality can meet Saudi Arabian standards.

Q2: How can I avoid supplier fraud?

A: Recommendations:

Use B2B platforms to verify suppliers (such as Alibaba Gold Supplier).

Visit the factory in person or entrust a third-party factory inspection.

Payment by letter of credit (LC) reduces transaction risk.

Q3: How long does it typically take to ship to Saudi Arabia?

A: Sea freight from major Chinese ports (such as Ningbo and Shanghai) to Saudi Arabia (such as Jeddah and Dammam) typically takes 18-25 days, depending on the route and transit times.

Q4: Is SASO certification required?

A: Yes, the Saudi market requires SASO certification for aluminum doors and windows, and many Chinese suppliers can assist with this process.

Q5: How can I further reduce logistics costs?

A: Possible solutions:

Concentrate shipments to reduce transport frequency.

Negotiate long-term freight discounts with freight forwarders.

Select suppliers near ports to reduce inland transportation costs.

Through these strategies, Saudi aluminum door and window manufacturers can effectively leverage the Chinese supply chain, significantly reduce costs, and enhance their market competitiveness.