Overview: The Global Competitiveness of Guangdong’s Aluminum Window and Door Accessories Industry

In today’s global construction and home furnishing market, aluminum windows and doors are highly favored for their excellent durability, modern aesthetics, and energy efficiency. As the world’s largest production base for aluminum window and door accessories, Guangdong has formed a complete industrial chain, from raw material supply and parts manufacturing to finished product assembly. Every year, tens of thousands of foreign buyers come here to source high-quality, competitively priced aluminum window and door accessories.

However, for foreign customers new to the Chinese supply chain, the procurement process often presents numerous challenges, including unclear quality standards, communication barriers, and complex logistics. This article aims to provide comprehensive guidance for foreign buyers, from understanding the unique advantages of Guangdong’s aluminum window and door accessories industry to avoiding procurement pitfalls and ultimately establishing stable and efficient supply chain relationships.

Part 1: Why Choose Guangdong Aluminum Window and Door Accessories?

- 1.1 Industrial Cluster Advantages: The World’s Most Complete Supply Chain Ecosystem

- Guangdong Province, especially Foshan, Dongguan, and Shenzhen, has formed the world’s largest and most comprehensive industrial cluster for aluminum window and door accessories. This cluster boasts:

- Specialized Division of Labor: From profile extrusion, hardware manufacturing, sealing strip production, to surface treatment (powder coating, anodizing, electrophoretic coating), each link has specialized manufacturers.

- Cost-Effectiveness: Large-scale production significantly reduces unit costs; prices are typically 20-50% lower than comparable European and American products.

- Innovation Ecosystem: Close collaboration between industry, academia, and research institutions leads to the introduction of hundreds of new designs and technological improvements every year.

- Convenient Logistics: The Pearl River Delta region has one of the world’s busiest port clusters (Shenzhen Port, Guangzhou Port) and a well-developed land transportation network.

- Guangdong Province, especially Foshan, Dongguan, and Shenzhen, has formed the world’s largest and most comprehensive industrial cluster for aluminum window and door accessories. This cluster boasts:

- 1.2 Technology and Quality: From “Made in China” to “Intelligent Manufacturing in China”

- In recent years, the Guangdong aluminum window and door accessories industry has undergone significant technological upgrades:

- Material Innovation:

- High-strength aluminum alloy formulations (6063-T5, 6061-T6, etc.)

- Environmentally friendly surface treatment technologies, complying with international standards such as RoHS and REACH

- Significantly improved performance of weather-resistant sealing materials (EPDM, silicone)

- Process Advancements:

- Precision mold manufacturing technology, with tolerance control within ±0.1mm

- Automation production lines are widely adopted, with a penetration rate of over 65%

- Intelligent manufacturing systems are widely used in leading enterprises

- Comprehensive Certifications:

- International general standards: ISO 9001 quality management system, ISO 14001 environmental management system

- Industry-specific certifications: American AAMA, European Qualicoat, Australian AS2047

- Energy-saving certifications: European energy-efficient window standards, US ENERGY STAR certification

- Material Innovation:

- In recent years, the Guangdong aluminum window and door accessories industry has undergone significant technological upgrades:

- 1.3 Design Diversity: Meeting Global Market Demands

- Guangdong manufacturers have shifted from simple imitation to independent design and innovation:

- Style Adaptability: A wide range of styles, from minimalist modern to classical decorative styles, is available.

- Climate Specificity: Specialized products are developed for different climate conditions, such as the high-cold regions of Northern Europe, the hot and humid regions of the Middle East, and the hurricane-prone areas of North America.

- Intelligent Integration: Intelligent accessories such as electric window openers, smart locks, and integrated sensors are becoming increasingly sophisticated.

- Guangdong manufacturers have shifted from simple imitation to independent design and innovation:

Part Two: Core Pain Points and Solutions for Foreign Customers’ Procurement

- 2.1 Pain Point One: Inconsistent Quality and Difficulty Identifying Reliable Suppliers

- Common Problems:

- Price differences for the same component can reach 300%, making it difficult to determine the corresponding quality.

- Inconsistent quality between samples and mass-produced products.

- Lack of internationally recognized third-party quality verification.

- Solutions:

- Four-step supplier screening method:

- Initial screening: Find manufacturers with export experience through platforms such as China International Aluminum Industry Exhibition, Alibaba International, and Global Trade.

- Qualification verification: Request ISO certificates, export records, and foreign customer recommendation letters.

- Factory audit: Conduct on-site or virtual factory inspections, focusing on production equipment, quality inspection processes, and raw material sources.

- Sample testing: Request samples to be sent to a third-party testing agency (such as SGS, BV) for professional testing.

- Key quality indicator checklist:

- Profile wall thickness (main profile ≥ 1.4mm)

- Hardware material (304 stainless steel is better than 201 stainless steel)

- Surface treatment thickness (powder coating ≥ 40μm, anodizing ≥ 10μm)

- Opening force test (casement window handle operating force ≤ 50N)

- Four-step supplier screening method:

- Common Problems:

- 2.2 Pain Point Two: Communication Barriers and Cultural Differences

- Common Problems:

- Language barriers lead to inaccurate communication of technical requirements.

- Inconsistent understanding of delivery time and payment terms.

- Unfamiliarity with international trade terms leads to an unclear division of responsibilities.

- Solutions:

- Establish an efficient communication mechanism:

- Professional purchasing agent: Employ a local purchasing agent or use bilingual technical communication personnel.

- Standardized documents: Use technical specifications with illustrations and text to avoid purely text-based descriptions.

- Regular video conferences: Conduct production progress communication at fixed times to establish direct contact.

- Cultural adaptability training: Understand the communication characteristics and decision-making processes in Chinese business culture.

- Key document checklist:

- Detailed technical drawings (annotating all dimensions, tolerances, and material requirements)

- Purchase contract (clearly defining international trade terms, such as FOB, CIF)

- Quality inspection standard agreement (AQL sampling standards, acceptance standards)

- Packaging requirements specifications (moisture-proof, anti-collision, pallet specifications)

- Establish an efficient communication mechanism:

- Common Problems:

- 2.3 Pain Point 3: Complex Logistics and Supply Chain Management

- Common Problems:

- Significant fluctuations in sea freight times, impacting project schedules

- Incomplete customs clearance documents leading to delays

- High rate of parts damage, making claims difficult

- Solutions:

- Optimized Logistics Strategy:

- Logistics Mode Selection:

- Small batches, high value: Air freight or express delivery

- Large batches, low time sensitivity: Full container load (FCL) sea freight

- Medium batches, high time sensitivity: Less than container load (LCL) sea freight + land transport combination

- Packaging Optimization:

- Hardware: Vacuum packaging + anti-rust paper + cardboard box

- Glass parts: Customized foam dividers + A-frame fixing

- Profiles: PE film wrapping + corner protection + steel strap fixing

- Supply Chain Visualization:

- Use a logistics tracking system to monitor cargo location in real time

- Establish safety stock to cope with sea freight delays

- Establish long-term cooperative relationships with freight forwarders to obtain priority service

- Logistics Mode Selection:

- Optimized Logistics Strategy:

- Common Problems:

- 2.4 Pain Point 4: Intellectual Property Protection and Product Compliance

- Common Problems:

- Designs are being copied, leading to price pressure

- Products not meeting the target market technical standards

- Failure to meet environmental requirements results in customs detention

- Solutions:

- Intellectual Property Protection Strategy:

- Legal protection: Apply for design patents in China (design patent protection period of 15 years)

- Technical protection: Segment core processes across different factories

- Contractual constraints: Sign strict confidentiality agreements and non-competition clauses

- Market monitoring: Regularly monitor target markets for counterfeit products

- Compliance Management:

- EU market: Ensure compliance with Construction Products Regulation (CPR) and CE certification requirements

- North American market: Comply with AAMA/WDMA/CSA 101/I.S.2/A440 standards

- Australian market: Obtain AS2047 certification

- Middle East market: Comply with UAE.S 501 and Saudi SASO standards

- Intellectual Property Protection Strategy:

- Common Problems:

Part 3: Step-by-Step Procurement Guide

- 3.1 Phase One: Needs Analysis and Market Research (1-2 weeks)

- Clarify Procurement Needs:

- Determine types of accessories (handles, hinges, pulleys, locks, sealing strips, etc.)

- Estimate procurement quantities (samples/small batch trial orders/large quantity orders)

- Determine budget range and quality requirements

- Understand the regulations and standards requirements of the target market

- Market Research:

- Attend industry exhibitions: China International Door & Window and Curtain Wall Expo, Canton Fair

- Online platform research: Alibaba International, Made-in-China, Global Sources

- Industry report analysis: Understand aluminum price trends and industry technological development trends

- Clarify Procurement Needs:

- 3.2 Phase Two: Supplier Screening and Evaluation (2-3 weeks)

- Find suppliers through multiple channels:

- B2B platforms: Screen for suppliers with “Gold Supplier” certification and more than 3 years of export experience

- Industry recommendations: Through industry associations and existing partners

- Exhibition contact: Directly communicate with exhibitors’ technical personnel to learn about the latest products

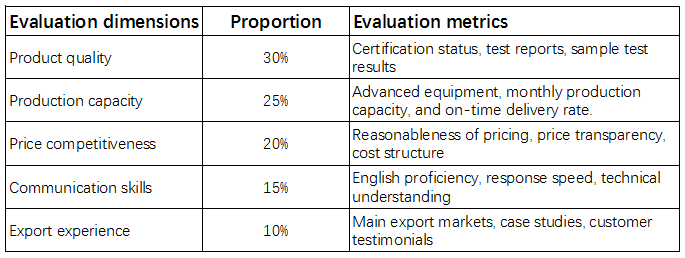

- Supplier evaluation matrix:

- Find suppliers through multiple channels:

- 3.3 Phase Three: Sample Testing and Negotiation (2-4 weeks)

- Sample Testing Process:

- Request representative samples from the supplier (3-5 sets)

- Conduct appearance inspection, dimensional measurement, and functional testing

- Commission a third-party laboratory for professional testing (corrosion resistance, durability, etc.)

- Conduct comparative analysis with existing products or competitors’ products

- Negotiation Points:

- Price negotiation: Based on quantity-based pricing, not simply price reduction

- Payment method: Attempt 30% advance payment + 70% payment upon receipt of bill of lading copy, gradually building trust

- Delivery time: Clearly define production cycle + transportation time, include penalty clauses for delayed delivery

- Quality assurance: Require a quality guarantee deposit (5-10% of the contract amount) or a quality guarantee period

- Sample Testing Process:

- 3.4 Phase Four: Trial Orders and Mass Procurement (4-8 weeks)

- Trial Order Management:

- Trial order quantity: Recommended to be 20-30% of the estimated monthly demand

- Trial order purpose: Verify batch consistency, packaging suitability, and logistics efficiency

- Trial order evaluation: Establish a detailed trial order evaluation form to record all issues

- Mass Procurement Optimization:

- Order batching: Avoid large-scale one-time purchases, place orders in batches to reduce risk

- Inventory management: Establish safety stock to cope with supply chain fluctuations

- Supplier development: Establish strategic cooperation with core suppliers to jointly improve products

- Trial Order Management:

- 3.5 Phase Five: Maintaining Long-Term Cooperative Relationships

- Deepening Cooperative Relationships:

- Regular performance evaluation: Evaluate supplier quality, delivery time, and service quarterly

- Joint improvement projects: Establish improvement teams to address common problems

- Information sharing: Share market trends and new product development directions

- Visits and exchanges: Regular mutual visits to strengthen understanding and trust

- Risk Management:

- Diversified supply: Cultivate 2-3 qualified suppliers to avoid single-source risk

- Contract renewal: Review contract terms annually to adapt to market changes

- Contingency plan: Develop contingency plans for supplier emergencies

- Deepening Cooperative Relationships:

Part 4: Technological Trends and Future Outlook

- 4.1 Intelligentization and Internet of Things Integration

- Modern aluminum door and window accessories are developing towards intelligent features:

- Smart handles: Integrating fingerprint, password, and Bluetooth unlocking functions

- Automatic window openers: Automatically controlled based on temperature, humidity, and air quality

- Safety sensors: Door and window status monitoring and intrusion alarms

- Energy management: Integrated with building energy management systems to optimize energy consumption

- Modern aluminum door and window accessories are developing towards intelligent features:

- 4.2 Sustainable Materials and Green Manufacturing

- Environmental trends are driving industry innovation:

- The proportion of recycled aluminum used has increased from 30% to over 50%

- Water-based coatings are replacing traditional solvent-based coatings

- Chromium-free surface treatment technology is becoming widespread

- Energy recovery and utilization in the production process

- Environmental trends are driving industry innovation:

- 4.3 Personalized Customization and Rapid Response

- Digital manufacturing technology is changing traditional production models:

- 3D printing technology used for prototyping complex parts

- Flexible production lines support small-batch, multi-variety production

- Virtual reality technology used for remote product display and design confirmation

- Cloud-based collaborative design systems

- Digital manufacturing technology is changing traditional production models:

- 4.4 Global Supply Chain Restructuring

- Supply chain changes in the post-pandemic era:

- Regionalized supply chains: Establishing assembly centers near major markets

- Digital supply chains: Blockchain technology applied to logistics tracking and quality traceability

- Resilient supply chains: Multi-regional production base layout to diversify risks

- Sustainable development: Carbon footprint tracking and reporting become a procurement consideration

- Supply chain changes in the post-pandemic era:

Part 5: FAQ

Q1: How significant is the quality gap between Guangdong aluminum door and window accessories and those from well-known European brands?

A: This gap is rapidly narrowing. Ten years ago, Guangdong products mainly competed in the low-end market, but now, many leading manufacturers’ products have obtained authoritative European certifications (such as Qualicoat, RAL) and achieved equivalent performance levels in testing. The main differences lie in brand premium and innovative design, but in terms of basic performance and durability, high-quality Guangdong products are already internationally competitive. The key is to choose manufacturers with R&D capabilities and a focus on quality, rather than just pursuing low prices.

Q2: What is the typical Minimum Order Quantity (MOQ)? Can small trial orders be accepted?

A: The MOQ varies depending on the product type and manufacturer:

Standard accessories (universal handles, hinges): usually 500-1000 sets

Customized accessories (special colors, specifications): usually 3000-5000 sets

Highly complex accessories (smart locks): usually 1000-2000 sets

Most high-quality suppliers accept small trial orders, but the unit price will be correspondingly higher. It is recommended to conduct sample testing first, and then verify mass production capabilities with a trial order (30-50% of the MOQ).

Q3: How long does it usually take from placing an order to the goods arriving at European and American ports?

A: The timeline is roughly as follows:

Production time: 15-25 days for standard products, 30-45 days for customized products

Export document preparation: 2-3 days

Sea freight time: 25-35 days to major European ports, 15-20 days to the US West Coast, 28-35 days to the East Coast

Customs clearance time: 3-7 days (if documents are complete)

The total time is usually between 45-75 days. It is recommended to plan ahead and consider possible delays (holidays, port congestion, etc.).

Q4: How are quality disputes handled? What guarantees are in place?

A: Prevention is better than cure; we recommend the following measures:

Clearly define standards beforehand: Specify acceptance criteria, testing methods, and AQL levels in the contract.

Third-party inspection: Arrange pre-shipment inspection (PSI) to resolve issues at the production site.

Quality guarantee deposit: Require suppliers to provide a quality guarantee deposit of 5-10% of the contract amount, with a retention period of 6-12 months.

Dispute resolution mechanism: Clearly define arbitration clauses in the contract (e.g., Hong Kong International Arbitration Centre).

In case of disputes, first attempt resolution through negotiation. Most suppliers value their reputation and are willing to cooperate in resolving issues. If negotiation fails, arbitration can be pursued according to the contract terms.

Q5: How do we ensure the products comply with our country’s building codes and standards?

A: We employ a four-tiered approach:

Supplier pre-qualification: Select manufacturers with experience exporting to your country.

Technical document review: Require suppliers to provide technical documents that comply with the target market standards.

Third-party certification: Commission certification testing from a locally accredited testing agency.

Responsibility allocation: Clearly state in the contract that the supplier must guarantee product compliance with specified standards, otherwise they bear full responsibility.

For critical projects, we recommend engaging a local engineering consultant to participate in technical specification development and acceptance.

Q6: What are the development cycle and cost of customized products?

A: Custom development typically involves three stages:

Design and development: 2-4 weeks, cost $1000-$5000 (depending on complexity)

Mold manufacturing: 4-8 weeks, cost $3000-$20000 (mold ownership needs to be clearly defined)

Sample testing: 2-3 weeks, cost to be negotiated between both parties

The total development cycle is approximately 8-15 weeks, with a cost of $5000-$25000. We recommend spreading the development cost across the first batch of orders or signing an exclusive use agreement with the supplier.

Q7: How do aluminum price fluctuations affect procurement prices? How do we manage price risk?

A: Aluminum prices account for 40-60% of the cost of aluminum doors and windows accessories, and their fluctuations directly impact procurement prices. Management strategies include:

Price linkage mechanism: Clearly define the aluminum price benchmark and adjustment formula in the contract.

Long-term agreements: Sign framework agreements with suppliers for 6-12 months to lock in prices or price ranges.

Futures hedging: Consider hedging with aluminum futures for large-scale purchases.

Diversified materials: Consider alternative materials in the design to reduce reliance on aluminum.

Q8: How do we assess the financial stability of suppliers?

A: Methods for evaluating the financial health of Chinese suppliers:

Credit reports: Obtain credit reports on Chinese companies through international agencies such as Dun & Bradstreet and Experian.

Bank references: Request letters of recommendation from the supplier’s main banks.

On-site observation: During visits, pay attention to the age and condition of equipment, employee morale, and the level of production activity.

Peer verification: Inquire with other foreign customers about payment terms and performance history.

Gradual cooperation: Start with small orders and gradually increase order volume to observe performance capabilities.

Summary

Guangdong, as a global manufacturing hub for aluminum door and window accessories, offers foreign buyers unparalleled product selection, cost advantages, and supply chain flexibility. The key to successful procurement lies in a systematic approach: in-depth market research, rigorous supplier evaluation, clear technical communication, comprehensive quality control, and continuous supplier relationship management.

With industry technological upgrades and digital transformation, Guangdong manufacturers are transforming from low-cost suppliers into technological partners. For foreign customers, this presents both challenges and opportunities – the challenge lies in identifying truly capable and quality-focused partners among numerous suppliers; the opportunity lies in accessing highly cost-effective and increasingly innovative product solutions.

Future successful international procurement strategies will be an art of balance: finding the optimal balance between cost and quality, standardization and customization, and short-term gains and long-term partnerships. By establishing supply chain partnerships based on mutual understanding and shared values, foreign buyers can not only obtain high-quality products but also maintain a competitive advantage in a rapidly changing market.

Ultimately, procuring aluminum door and window accessories from Guangdong is not simply a commodity transaction, but a process of cross-cultural business cooperation and technological exchange. Those buyers who invest time in understanding the Chinese market, building local networks, and cultivating long-term partnerships will reap the greatest rewards in this world’s largest manufacturing base.